Holonomic constraints: Difference between revisions

en>R.e.b. m →References: Fixing style/layout errors |

en>AHusain314 m Repeated Reference |

||

| Line 1: | Line 1: | ||

[[Image:Gear pump.png|thumb|Gearpump with external teeth, note the rotational direction of the gears. For most people this is counterintuitive]][[Image:Gear pump 3.png|thumb|Gearpump with internal teeth]] | |||

[[Image:Gerotor anm.gif|right|thumb|A gerotor (image does not show intake or exhaust)]] | |||

[[Image:Rotary vane pump.svg|thumb|Fixed displacement vane pump]] | |||

[[Image:Screwpump.gif|thumb|Principle of screw pump (Saugseite = intake, Druckseite = outflow)]] | |||

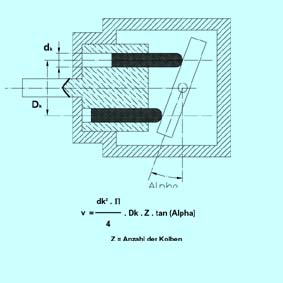

[[Image:Swashplate.jpg|thumb|Axial piston pump, swashplate principle]] | |||

[[Image:Radiale plunjerpomp.png|thumb|Radial piston pump]] | |||

'''Hydraulic pumps''' are used in [[hydraulic drive system]]s and can be hydrostatic or hydrodynamic. | |||

Hydrostatic pumps are [[positive displacement pump]]s while hydrodynamic pumps can be fixed displacement pumps, in which the displacement (flow through the pump per rotation of the pump) cannot be adjusted, or [[variable displacement pump]]s, which have a more complicated construction that allows the displacement to be adjusted. | |||

==Hydraulic pump types== | |||

===Gear pumps=== | |||

[[Gear pump]]s (with external teeth) (fixed displacement) are simple and economical pumps. The swept volume or [[Engine displacement|displacement]] of gear pumps for hydraulics will be between about 1 cm<sup>3</sup> (0.001 litre) and 200 cm<sup>3</sup> (0.2 litre). They have the lowest [[volumetric efficiency]] (<math> \eta_v \approx 90 % </math> ) of all three basic pump types (gear, vane and piston pumps) <ref>Parr, Andrew (2011). "Hydraulics and Pneumatics a technician's and engineer's guide", p. 38. Elsevier.</ref> These pumps create pressure through the meshing of the gear teeth, which forces fluid around the gears to pressurize the outlet side. For lubrication, the gear pump uses a small amount of oil from the pressurized side of the gears, bleeds this through the (typically) hydrodynamic bearings, and vents the same oil either to the low pressure side of the gears, or through a dedicated drain port on the pump housing. Some gear pumps can be quite noisy, compared to other types, but modern gear pumps are highly reliable and much quieter than older models. This is in part due to designs incorporating split gears, helical gear teeth and higher precision/quality tooth profiles that mesh and unmesh more smoothly, reducing pressure ripple and related detrimental problems. Another positive attribute of the gear pump, is that catastrophic breakdown is a lot less common than in most other types of hydraulic pumps. This is because the gears gradually wear down the housing and/or main bushings, reducing the volumetric efficiency of the pump gradually until it is all but useless. This often happens long before wear causes the unit to seize or break down. | |||

===Rotary vane pumps=== | |||

Rotary vane pumps (fixed and simple adjustable displacement) have higher efficiencies than gear pumps, but are also used for mid pressures up to 180 bars in general. Modern units can exceed 300 bars in continuous operation, although vane pumps are not regarded as "high pressure" components. Some types of vane pumps can change the centre of the vane body, so that a simple adjustable pump is obtained. These adjustable vane pumps are in general constant pressure or constant power pumps: the displacement is increased until the required pressure or power is reached and subsequently the displacement or swept volume is decreased until an equilibrium is reached. A critical element in vane pump design is how the vanes are pushed into contact with the pump housing, and how the vane tips are machined at this very point. Several type of "lip" designs are used, and the main objective is to provide a tight seal between the inside of the housing and the vane, and at the same time to minimize wear and metal-to-metal contact. Forcing the vane out of the rotating center and towards the pump housing is accomplished using spring-loaded vanes, or more traditionally, vanes loaded hydrodynamically (via the pressurized system fluid). | |||

===Screw pumps=== | |||

[[Screw pump]]s (fixed displacement) consist of two [[Archimedes' screw]]s that intermesh and are enclosed within the same chamber. These pumps are used for high flows at relatively low pressure (max 100 bar). They were used on board ships where a constant pressure hydraulic system extended through the whole ship, especially to control [[ball valve]]s but also to help drive the steering gear and other systems. The advantage of the screw pumps is the low sound level of these pumps; however, the efficiency is not high. | |||

The major problem of screw pumps is that the hydraulic reaction force is transmitted in a direction that's axially opposed to the direction of the flow. | |||

There are two ways to overcome this problem: | |||

(1) put a thrust bearing beneath each rotor; | |||

(2) create a hydraulic balance by directing a hydraulic force to a piston under the rotor. | |||

Types of screw pumps: | |||

(1) single end <br /> | |||

(2) double end <br /> | |||

(3) single rotor <br /> | |||

(4) multi rotor timed <br /> | |||

(5) multi rotor untimed. | |||

===Bent axis pumps=== | |||

[[Bent axis pump]]s, axial piston pumps and motors using the bent axis principle, fixed or adjustable displacement, exists in two different basic designs. The Thoma-principle (engineer Hans Thoma, Germany, patent 1935) with max 25 degrees angle and the Wahlmark-principle (Gunnar Axel Wahlmark, patent 1960) with spherical-shaped pistons in one piece with the piston rod, piston rings, and maximum 40 degrees between the driveshaft centerline and pistons (Volvo Hydraulics Co.). These have the best efficiency of all pumps. Although in general the largest displacements are approximately one litre per revolution, if necessary a two-liter swept volume pump can be built. Often variable-displacement pumps are used, so that the oil flow can be adjusted carefully. These pumps can in general work with a working pressure of up to 350–420 bars in continuous work. | |||

===Axial piston pumps swashplate principle=== | |||

[[Axial piston pump]]s using the [[swashplate]] principle (fixed and adjustable displacement) have a quality that is almost the same as the bent axis model. They have the advantage of being more compact in design. The pumps are easier and more economical to manufacture; the disadvantage is that they are more sensitive to oil contamination. | |||

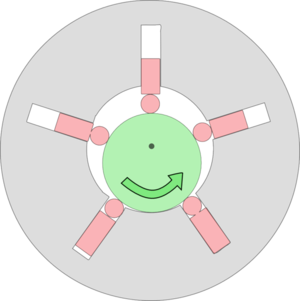

===Radial piston pumps=== | |||

[[Radial piston pump]]s are used especially for high pressure and relatively small flows. Pressures of up to 650 bar are normal. In fact variable displacement is possible. The pump is designed in such a way that the plungers are connected to a floating ring. This floating ring can be moved horizontally by a control lever & thus causes an eccentricity in the center of rotation of the plungers. The amount of eccentricity can be controlled to vary the discharge. The suction & discharge can be totally reversed seamlessly by shifting the eccentricity to the opposite side. Hence both quantity & direction can be varied in a radial piston pump, just as in the Swash plate pump. | |||

===Peristaltic pumps=== | |||

[[Peristaltic pump]]s are not generally used for high pressures. | |||

== Pumps for open and closed systems == | |||

Most pumps are working in open systems. The pump draws oil from a reservoir at [[atmospheric pressure]]. It is very important that there is no [[cavitation]] at the suction side of the pump. For this reason the connection of the suction side of the pump is larger in diameter than the connection of the pressure side. In case of the use of multi-pump assemblies, the suction connection of the pump is often combined. It is preferred to have free flow to the pump (pressure at inlet of pump at least 0.8 bars). The body of the pump is often in open connection with the suction side of the pump. | |||

In case of a closed system, both sides of the pump can be at high pressure. The reservoir is often pressurized with 6-20 bars boost pressure. For closed loop systems, normally axial piston pumps are used. Because both sides are pressurized, the body of the pump needs a separate leakage connection. | |||

== Multi pump assembly == | |||

In a hydraulic installation, one pump can serve several cylinders and motors. However, in that case a constant pressure system is required and the system always needs full power. It is more economic to give each cylinder and motor its own pump. In that case, multi-pump assemblies can be used. Gear pumps are often supplied as multi-pumps. The different chambers (sometimes of different sizes) are mounted in one body or built together. Vane pumps and gerotor pumps too are often available as multi-pumps. Screw pumps can be combined with gear or vane pumps. Axial piston swashplate pumps can be combined with a second pump, or with one or more gear pumps or vane pumps (the gear or vane pumps often serving as flush pumps for cooling larger units). Axial plunger pumps of the bent-axis design cannot be combined with other pumps. | |||

== Hydraulic pumps, calculation formulas== | |||

===Flow=== | |||

<math>Q = n \cdot V_{stroke} \cdot \eta_{vol}</math> | |||

where | |||

:<math> | |||

\begin{align} | |||

Q &= \text{Flow in cubic meter per second } & \left[ \frac{m^3}{s} \right] \\ | |||

n &= \text{revolution per second} & \left[ \frac{rev}{s} \right] \\ | |||

V_{stroke} &= \text{Swept volume in cubic meters} & \left[ m^3 \right] \\ | |||

\eta_{vol} &= \text{Volumetric efficiency} & \left[\right] | |||

\end{align} | |||

</math> | |||

===Power=== | |||

<math>P = {n \cdot V_{stroke} \cdot \Delta p \over ~\eta_{mech,hydr}}</math> | |||

where | |||

:<math> | |||

\begin{align} | |||

P &= \text{Power in Watt} & \left[ \frac{Nm}{s} \right] \\ | |||

n &= \text{Revolution per second} & \left[ \frac{rev}{s} \right] \\ | |||

V_{stroke} &= \text{swept volume} & \left[ m^3 \right]\\ | |||

\Delta p &= \text{pressure difference over pump} & \left[ \frac{N}{m^2} \right]\\ | |||

\eta_{mech,hydr} &= \text{Mechanical/hydraulic efficiency} & \left[\right] | |||

\end{align} | |||

</math> | |||

==References== | |||

<references /> | |||

==External links== | |||

{{Commons|Gear pump}} | |||

*[http://www.pumpschool.com/principles/external.htm External gear pump description] | |||

*[http://www.pumpschool.com/principles/internal.htm Internal gear pump description] | |||

==See also== | |||

*[[Vane pump]] | |||

{{Hydraulics}} | |||

<br /> | |||

{{DEFAULTSORT:Hydraulic Pump}} | |||

[[Category:Pumps]] | |||

[[Category:Hydraulics|Pump, Hydraulic]] | |||

Latest revision as of 05:15, 29 October 2013

Hydraulic pumps are used in hydraulic drive systems and can be hydrostatic or hydrodynamic.

Hydrostatic pumps are positive displacement pumps while hydrodynamic pumps can be fixed displacement pumps, in which the displacement (flow through the pump per rotation of the pump) cannot be adjusted, or variable displacement pumps, which have a more complicated construction that allows the displacement to be adjusted.

Hydraulic pump types

Gear pumps

Gear pumps (with external teeth) (fixed displacement) are simple and economical pumps. The swept volume or displacement of gear pumps for hydraulics will be between about 1 cm3 (0.001 litre) and 200 cm3 (0.2 litre). They have the lowest volumetric efficiency ( ) of all three basic pump types (gear, vane and piston pumps) [1] These pumps create pressure through the meshing of the gear teeth, which forces fluid around the gears to pressurize the outlet side. For lubrication, the gear pump uses a small amount of oil from the pressurized side of the gears, bleeds this through the (typically) hydrodynamic bearings, and vents the same oil either to the low pressure side of the gears, or through a dedicated drain port on the pump housing. Some gear pumps can be quite noisy, compared to other types, but modern gear pumps are highly reliable and much quieter than older models. This is in part due to designs incorporating split gears, helical gear teeth and higher precision/quality tooth profiles that mesh and unmesh more smoothly, reducing pressure ripple and related detrimental problems. Another positive attribute of the gear pump, is that catastrophic breakdown is a lot less common than in most other types of hydraulic pumps. This is because the gears gradually wear down the housing and/or main bushings, reducing the volumetric efficiency of the pump gradually until it is all but useless. This often happens long before wear causes the unit to seize or break down.

Rotary vane pumps

Rotary vane pumps (fixed and simple adjustable displacement) have higher efficiencies than gear pumps, but are also used for mid pressures up to 180 bars in general. Modern units can exceed 300 bars in continuous operation, although vane pumps are not regarded as "high pressure" components. Some types of vane pumps can change the centre of the vane body, so that a simple adjustable pump is obtained. These adjustable vane pumps are in general constant pressure or constant power pumps: the displacement is increased until the required pressure or power is reached and subsequently the displacement or swept volume is decreased until an equilibrium is reached. A critical element in vane pump design is how the vanes are pushed into contact with the pump housing, and how the vane tips are machined at this very point. Several type of "lip" designs are used, and the main objective is to provide a tight seal between the inside of the housing and the vane, and at the same time to minimize wear and metal-to-metal contact. Forcing the vane out of the rotating center and towards the pump housing is accomplished using spring-loaded vanes, or more traditionally, vanes loaded hydrodynamically (via the pressurized system fluid).

Screw pumps

Screw pumps (fixed displacement) consist of two Archimedes' screws that intermesh and are enclosed within the same chamber. These pumps are used for high flows at relatively low pressure (max 100 bar). They were used on board ships where a constant pressure hydraulic system extended through the whole ship, especially to control ball valves but also to help drive the steering gear and other systems. The advantage of the screw pumps is the low sound level of these pumps; however, the efficiency is not high.

The major problem of screw pumps is that the hydraulic reaction force is transmitted in a direction that's axially opposed to the direction of the flow.

There are two ways to overcome this problem:

(1) put a thrust bearing beneath each rotor;

(2) create a hydraulic balance by directing a hydraulic force to a piston under the rotor.

Types of screw pumps:

(1) single end

(2) double end

(3) single rotor

(4) multi rotor timed

(5) multi rotor untimed.

Bent axis pumps

Bent axis pumps, axial piston pumps and motors using the bent axis principle, fixed or adjustable displacement, exists in two different basic designs. The Thoma-principle (engineer Hans Thoma, Germany, patent 1935) with max 25 degrees angle and the Wahlmark-principle (Gunnar Axel Wahlmark, patent 1960) with spherical-shaped pistons in one piece with the piston rod, piston rings, and maximum 40 degrees between the driveshaft centerline and pistons (Volvo Hydraulics Co.). These have the best efficiency of all pumps. Although in general the largest displacements are approximately one litre per revolution, if necessary a two-liter swept volume pump can be built. Often variable-displacement pumps are used, so that the oil flow can be adjusted carefully. These pumps can in general work with a working pressure of up to 350–420 bars in continuous work.

Axial piston pumps swashplate principle

Axial piston pumps using the swashplate principle (fixed and adjustable displacement) have a quality that is almost the same as the bent axis model. They have the advantage of being more compact in design. The pumps are easier and more economical to manufacture; the disadvantage is that they are more sensitive to oil contamination.

Radial piston pumps

Radial piston pumps are used especially for high pressure and relatively small flows. Pressures of up to 650 bar are normal. In fact variable displacement is possible. The pump is designed in such a way that the plungers are connected to a floating ring. This floating ring can be moved horizontally by a control lever & thus causes an eccentricity in the center of rotation of the plungers. The amount of eccentricity can be controlled to vary the discharge. The suction & discharge can be totally reversed seamlessly by shifting the eccentricity to the opposite side. Hence both quantity & direction can be varied in a radial piston pump, just as in the Swash plate pump.

Peristaltic pumps

Peristaltic pumps are not generally used for high pressures.

Pumps for open and closed systems

Most pumps are working in open systems. The pump draws oil from a reservoir at atmospheric pressure. It is very important that there is no cavitation at the suction side of the pump. For this reason the connection of the suction side of the pump is larger in diameter than the connection of the pressure side. In case of the use of multi-pump assemblies, the suction connection of the pump is often combined. It is preferred to have free flow to the pump (pressure at inlet of pump at least 0.8 bars). The body of the pump is often in open connection with the suction side of the pump.

In case of a closed system, both sides of the pump can be at high pressure. The reservoir is often pressurized with 6-20 bars boost pressure. For closed loop systems, normally axial piston pumps are used. Because both sides are pressurized, the body of the pump needs a separate leakage connection.

Multi pump assembly

In a hydraulic installation, one pump can serve several cylinders and motors. However, in that case a constant pressure system is required and the system always needs full power. It is more economic to give each cylinder and motor its own pump. In that case, multi-pump assemblies can be used. Gear pumps are often supplied as multi-pumps. The different chambers (sometimes of different sizes) are mounted in one body or built together. Vane pumps and gerotor pumps too are often available as multi-pumps. Screw pumps can be combined with gear or vane pumps. Axial piston swashplate pumps can be combined with a second pump, or with one or more gear pumps or vane pumps (the gear or vane pumps often serving as flush pumps for cooling larger units). Axial plunger pumps of the bent-axis design cannot be combined with other pumps.

Hydraulic pumps, calculation formulas

Flow

where

Power

where

References

- ↑ Parr, Andrew (2011). "Hydraulics and Pneumatics a technician's and engineer's guide", p. 38. Elsevier.

External links

Most brokers paid and post their listings at these online property categorised portals but fail to realise that there is simply extra to it. They fail to leverage on one of the vital well-liked on-line advertising and marketing tool of their marketing campaign and that is through the social media.

In case you are among the many few who've passed the grueling Actual Estate Salesperson (RES) course, congratulations. So what next? Which agency should you be a part of? Earlier than taking the plunge, you will need to choose the proper mentor who can educate you the ropes in actual estate. An excellent mentor will allow you to navigate the complex world of real property by instructing you the way to get listings, advertising and marketing methods, real estate contracts and methods to closing your deal. He will even caution you on errors to keep away from that would land you in trouble. This has been reflected within the Industrial Production reading index for prescribed drugs. In June, the reading fell to one hundred thirty from 287. Effectively if you do not, you then're simply leaving your actual property enterprise to chance. Commons for rent

Thanks to hirepropertyagent.com.sg, i've discovered myself a good agent. He did a great job promoting my property and it was bought at an excellent value." JLL appointed unique agent for the sale of 2, 4 and 6 Dunlop Street by Expression of Curiosity. Uncommon Industrial Growth inside Pandan Meals Zone space up for sale conserving you updated with the property market 3. Work @ Residence IT Solutions As property costs cool in Hong Kong and Singapore, which have lengthy been magnets for Chinese language funding, extra money is flowing to actual property markets comparable to New York, London and Sydney. Chinese language have overtaken Russians house for sale in singapore the primary time as the biggest buyers of flats in Manhattan, in response to actual estate brokers. Condominium For Lease – Tribeca by the Waterfront (D09)

Property developer and residential landlord for flats and homes for lease and sale. Most property firms share the same database of property listings in Singapore. Due to this fact it is best to solely use only ONE agent at a time. In case you approach many agents at the similar time, very likely that they'll present you the same property. A lot confusion and embarrassment will arise should you engage many brokers. One of the best, and most of the time only, strategy to discover a good property agent in Singapore is phrase-of-mouth. Ask your friends and colleagues for reference. It is very simple to provide you with a couple of candidates since a lot of the expatriates dwelling in Singapore for a long time can have several good agent contacts to guide you. Toa Payoh, Singapore Singapore 319378 Estate

This is precisely what happened to me and my husband at the moment, to not point out a very unscrupulous developer operating in a really unprofessional manner. I need to share this story with everyone here, and please pass the message round particularly among expats communities, beware while you want to purchase property developed by VicLand Pte Ltd and if developer's agent is ECG property. There was only one unit left on the market by developer, 03-09, a 3 bed room flat. On the time my husband was out of town, and initially I liked what I saw so I instructed the developer's agent and my agent we should come back with my husband in two weeks to view it once more and make a decision after ward. Complaint / Suggestions about lousy property agent Darren Ng from Dennis Wee

This bought me thinking and I started to surprise – how much does a property agent really earn? We often hear or read about sure brokers making million dollar commissions, however is that the exception or the norm? That piqued my curiosity. Like any job, those who put in time and effort will do well and rise to the top. The ethics of exhausting work apply to the true property market as nicely. For individuals who are pondering of making a career change to develop into a property agent, you should be ready to invest the trouble to do properly. Otherwise you may just add to the statistic of brokers who eventually drop out of the realtor game. Properties that do not fall within the definition of residential properties stated above are non-residential properties Web site - www.riaschool.com.sg

Ought to you are on the lookout for new properties for investment or for own stay, we offer property recommendation and search services tailored to your needs. We have represented many together with worldwide and local buyers in efficiently finishing their property purchases. We work with main builders to bring you the latest and one of the best prime properties in Singapore. We are a one-cease service that may full your property cycle from purchase to sale. Property agents for Singapore Land Authority protecting among the government colonial properties for rent. Property leases for expatriates and foreigners. Also helps expats to purchase and promote their properties as well as property investment opportunities in Singapore and China. The Restaurant Affiliation of Singapore